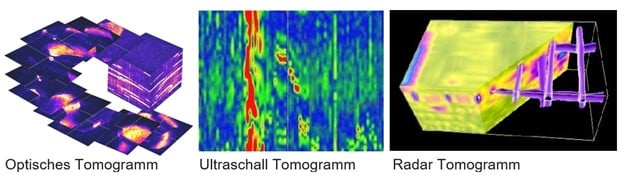

If the variables sought (density, heat capacity, dielectric constant, optical properties, transit time, humidity, .….) are recorded tomographically, the results can typically be displayed in all 3 dimensions. The amplitude and/or the phase of the response function can be extracted.